Homemade Sheet Metal Plenum Box

Sheet metal products 8 x 20 x 20 in.

Homemade sheet metal plenum box. Simply measure and cut to size using tin snips to match the supply opening of the air handler furnace or evaporator coil. It s like a little metal sandwich. The trim to fit plenum fully assembled measures 20 in. Colorado box company 1 empire metal products 1 first co 1 friedrich air conditioning 1 green metals 1.

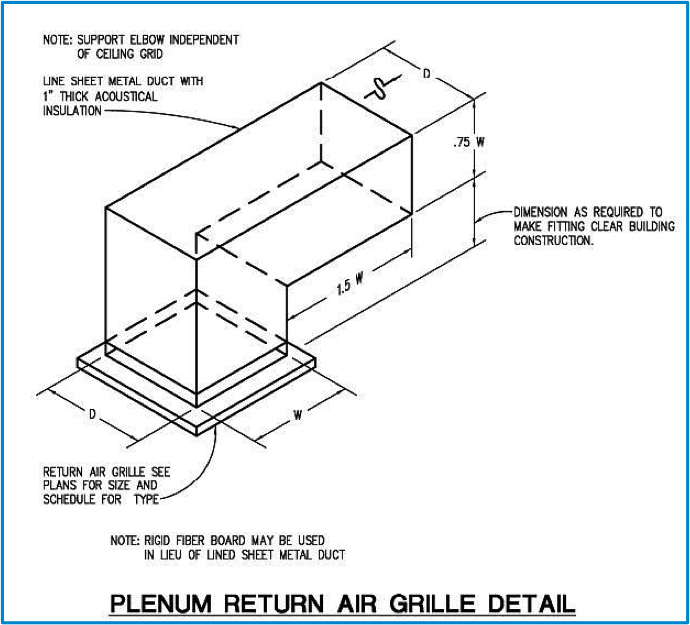

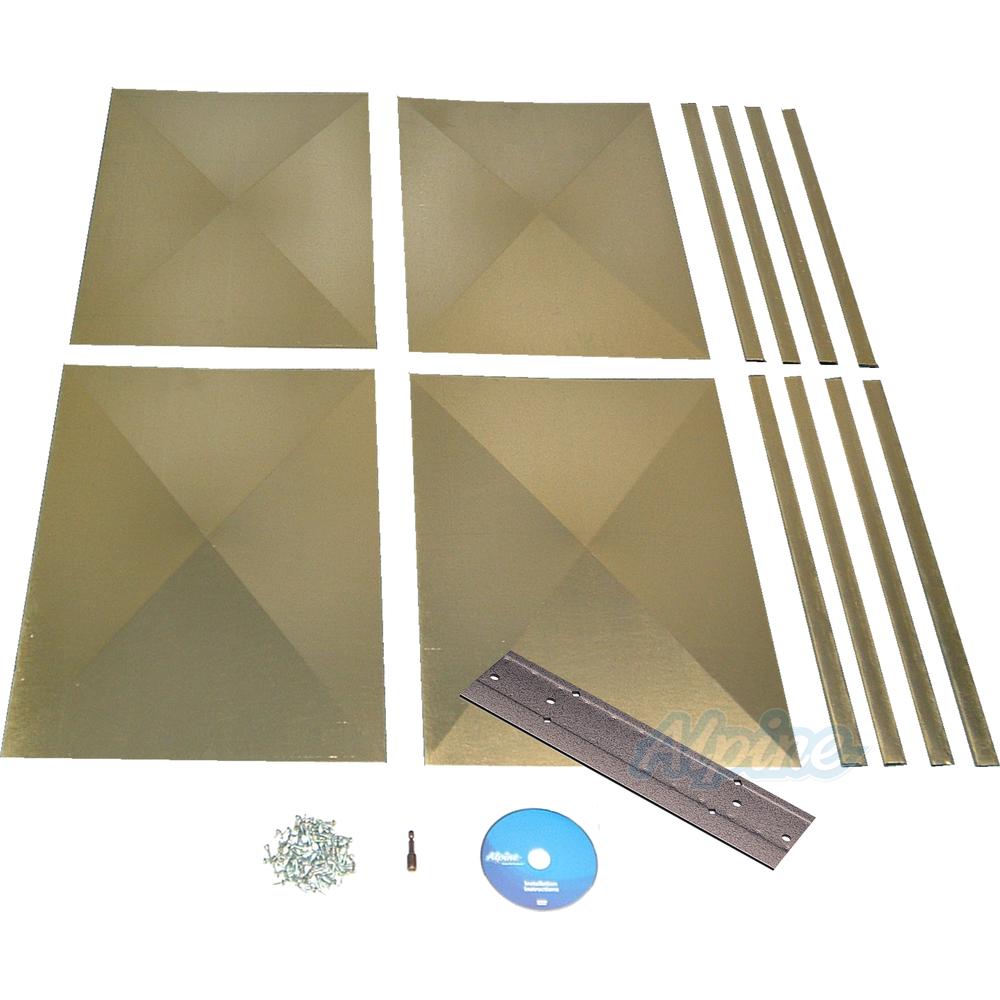

2 end caps if product name specifies flat. 26 ga duct plenum. After bending a box or pan form is then completed by screw solder weld rivet or other metal fixing process. Constructed of 26 gauge sheet metal the knock down design of the plenum takes up very little space and simplifies transporting to the job site.

Tape the flaps down with foil tape to complete the duct board. In a box and pan brake the clamping bar includes several removable blocks which may be removed and rearranged to permit bending of restricted areas of a piece of sheet metal or of already partially formed pieces. Place the sheet metal in the correct position on the positive die and slide the negative on top. Place this cylinder on top of the metal sandwich and place the entire assembly under the press.

Staple the foil to the duct board. M2430v1 vertical plenum heating air handler module 1 m3642v1 vertical plenum heating air handler module 1. Slit the foil vapor barrier extending beyond the edges of the duct board with a duct board knife. Start with making the long side of the planter box.

They are designed to be used with multiple different brands and can be customized for your ductwork needs. Take 2 4 and cut two pieces to 65 in length and one piece to 19. Find a long metal cylinder that will fit between the two stainless steel rods. Drill pocket holes using kreg jig as shown in the picture.

Fold the ends of the foil onto the outside of the duct board. Secure the end caps to the plenum. Then take 2 6 and cut two pieces to 26 in length.