How Far Are Purlins Spaced On A Metal Roof Overlay

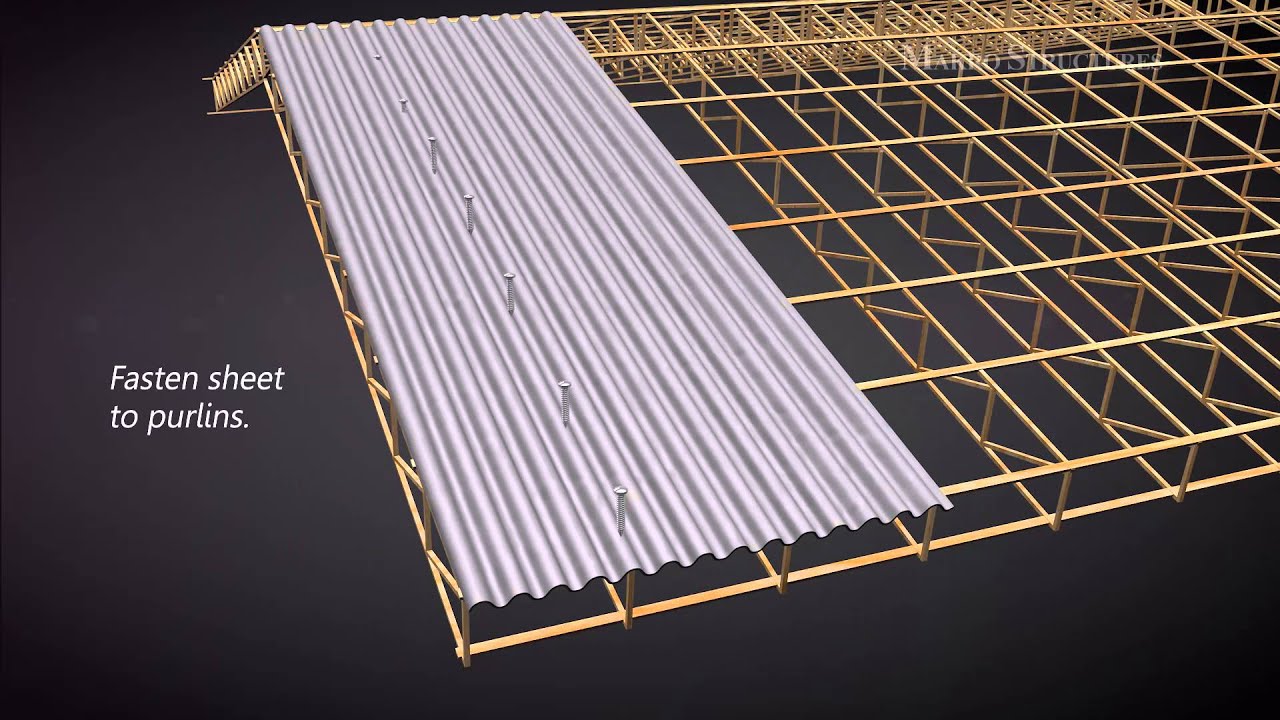

Twenty four inches is a common spacing of furring strips for a metal roof.

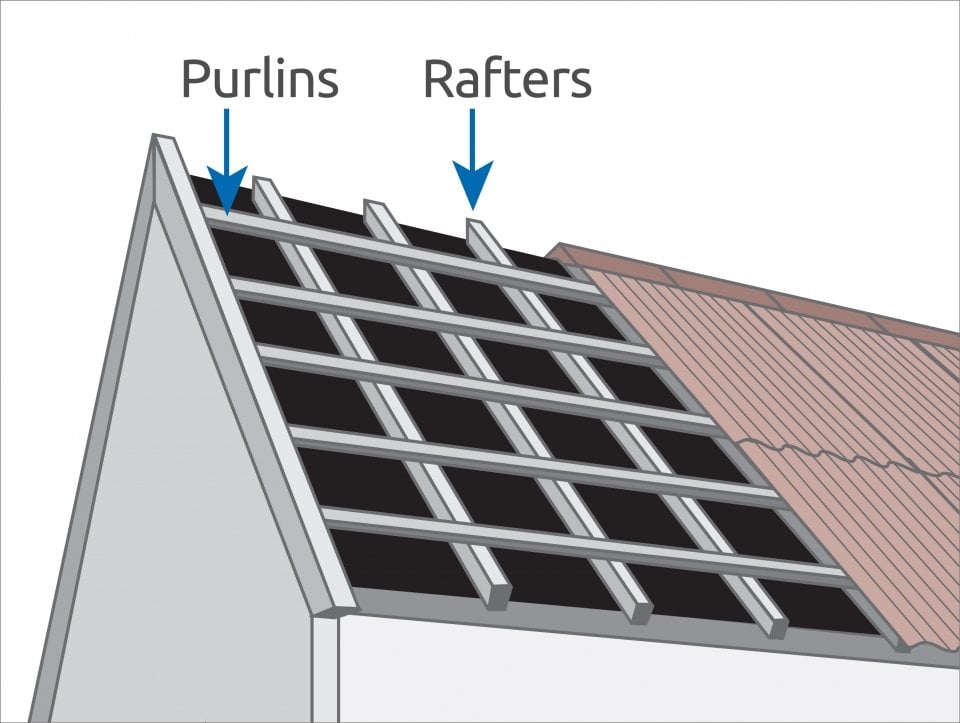

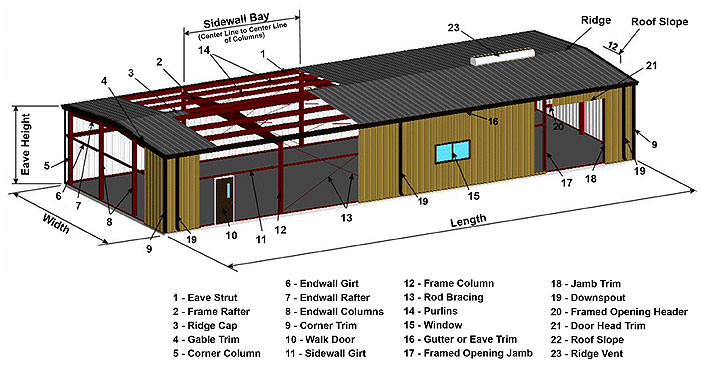

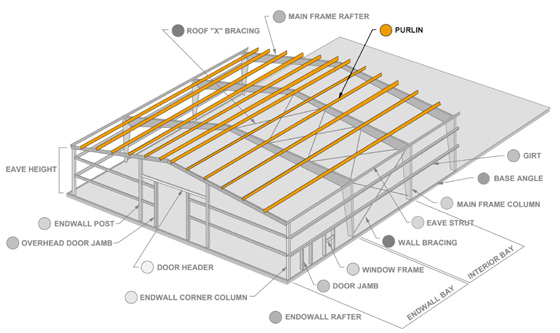

How far are purlins spaced on a metal roof overlay. When positioned roof purlins should be spaced no further than 1 2 metres apart when using sheeting with a thickness of 0 7mm and 1 metre when using 0 5mm sheeting. The purpose of the purlins is to provide a solid foundation for the metal roofing panels and trim to be screwed to. Exact requirements will vary but as a rough guide this is a good rule of thumb to follow. Purlins are 2 by 4 feet and are installed much like metal roofing.

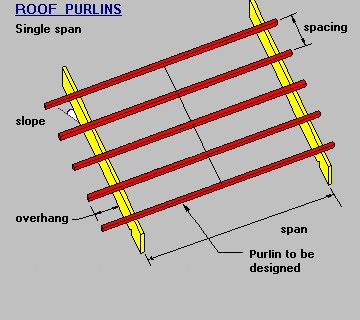

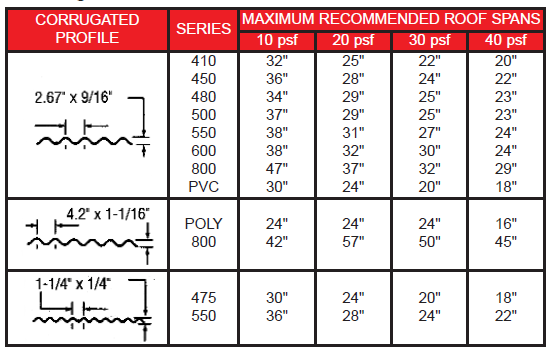

For the lighter material such as lightweight aluminum the common spacing length is 4 inches of clear gap. The diagram above is a typical 37 wide panel and the spacing works out perfectly. For heavier material such as gage steel the metal roof purlins spacing length could go up to 4 feet. For 2x6s purlins the posts are spaced in 6 feet distance.

Purlin spacing is dependent on profile of the metal and gauge plus snow and wind load plus what the rafters are designed to carry. For 2x4s purlins the posts are spaced in 4 feet distance. They give added support to the roof and also provide a nailing surface for the end panels and drip edge. I am installing ribbed metal panels over a singlt slope roof on a new workshop.

However sometimes corrugated sheets are 39 wide instead of 37 wide. By the standard the most used placement of purlin span for metal roof is five foot intervals. I was planning to install directly over 2x4 purlins which are mostly already installed. Metal roof purlins are installed horizontally under metal roofs.

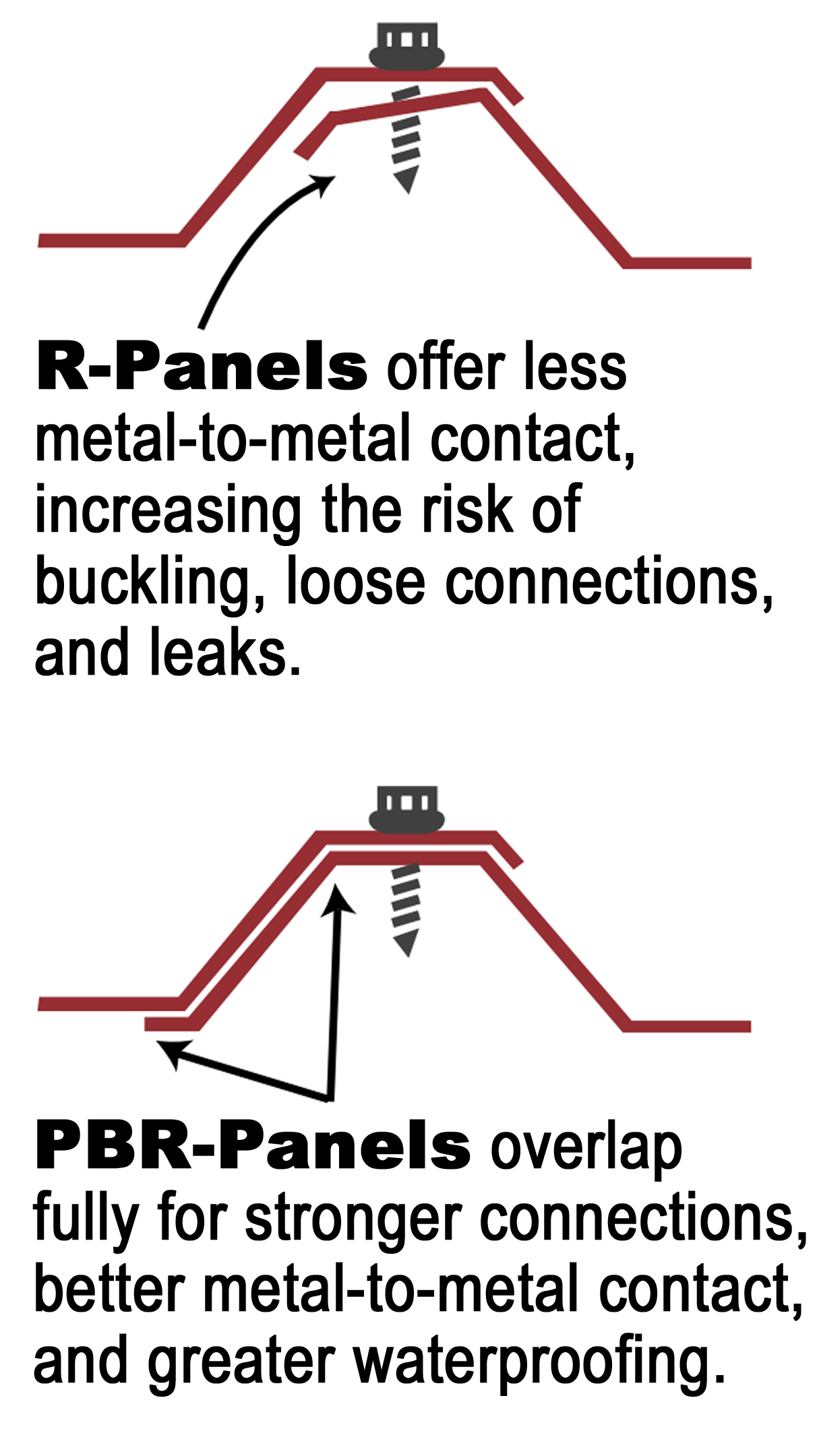

If the space between posts is greater than 8 feet then brace is needed to avoid buckling. Edit answer for another 41 minute you need to check the installation instructions from the manufacturer depending on whether the purlins firring strips are 1x or 2x material and how wide thickness metal gage of roofing steel or aluminum type of seams design wind and snow loading whether designed to be walked on or not etc i have seen it vary from as little as 4 inches clear gap between firring strips on lightweight aluminum to as much as 4 feet on very heavy gage. Correctly measure the spacing of furring strips for a metal roof to further decrease condensation. Purlin spacing for metal roofing.

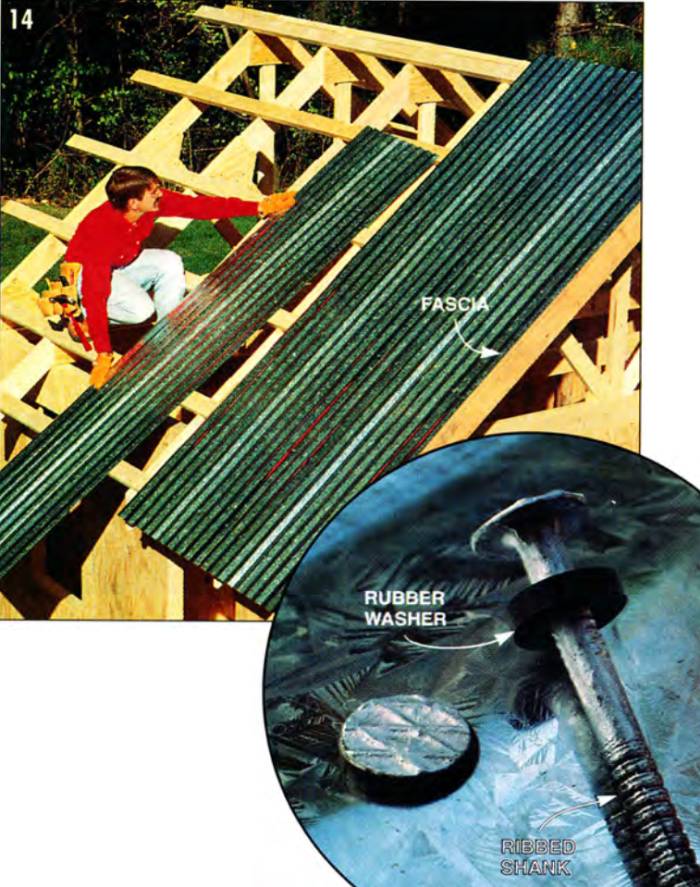

This shop will be insulated but mostly unheated except when i m working in there say 10 hours a week. There will be four screws per screw line placed in the high of the corrugated panel. The typical spacing standards for residential and commercial buildings are about 1 to 2 foot. Purlins are non pressure treated 1 x 4 x 12 lumber that is installed on to the roof in a specific layout pattern and screw pattern.

Fyi we run purlins on 3 5 feet on center depending on size of purlin.