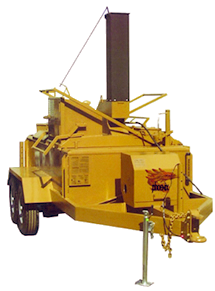

Hot Asphalt Roofing Kettle

All seasons equipment hot asphalt kettle 1250 gal.

Hot asphalt roofing kettle. Proper safety training is. However this is more challenging in the winter. Asphalt impregnated roofing felts are installed in overlapping courses during the asphalt application in order to strengthen the resulting roof membrane. Solid asphalt a by product of petroleum refining processes is melted on site in an industrial asphalt kettle and applied to the roof as a hot liquid.

Typical asphalt built up roofs have three or four plies. In order to properly install built up roofing systems burs and other asphalt roof systems with hot mopping you must heat the asphalt to the correct temperature in the kettle and apply it to the roof at its application temperature. At the end of the installation gravel is typically set into an additional surface. Kettle parts frame run gear.

Hot mopping on asphalt roofs is highly dangerous. Kettle engine replacement part. Kettle parts lp butane. Our tar kettles and tar kettle roofing equipment from roofmaster are built for the longest life and reliability.

We have all type of hot tar asphalt roofing equipment including sprayers material carts mop carts hot asphalt carriers hot luggers asphalt pour pots tar buckets moppers mops and related commercial roofing equipment. Kettle parts valves. All seasons equipment kettle skimmer standard. Knives blades.

A layer of felt and asphalt is called a ply.