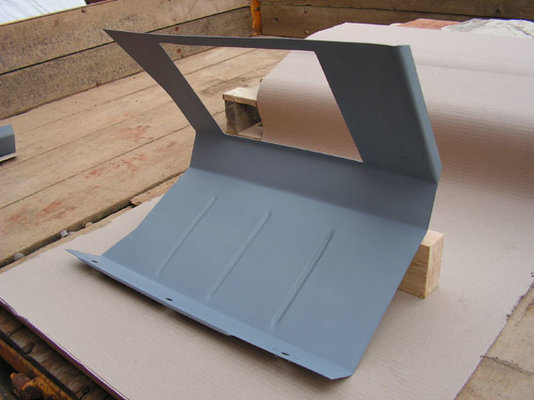

Homemade Sheet Metal Stiffening Ribs

Pressing grooves ribs or designs into a piece of sheet metal will greatly increase the strength.

Homemade sheet metal stiffening ribs. Apr 13 2017 sheet metal brackets with stiffening ribs. Sorry i have no idea about formulas for this. Rib length height shape and more is taken into consideration and we discuss which modifications fabricators can benefit from most. Any form in the sheet metal will make it stronger as well as ribs consider dimples in the local area.

Anyway in addition to what everyone else has suggested basic good design for stiffening sheet metal is to stagger your stiffeners so instead of putting all the bumps in a row which simply makes the gap down the center the weakest point you d want 3 smaller bumps in the intermediate rows so it would be 2 3 2 3 2. Accurl machine tools 95 535 views. The stiffening rib is added to the bracket at the bending stage by separating the bottom bend blocks and inserting a metal strip in the gap which then forms a rib at the same time as the angle bend. A method of forming intersecting stiffener ribs in a flat sheet of deformable metal having outer edges comprising the steps of cutting a pair of interconnected slit means in said sheet in the form.

Making stronger stiffening ribs webinar in this webinar we look at how fabricators traditionally form stiffening ribs and how there may be better more effective ways to form ribs. Panel w stiffening ribs flat panel snap on standing seam metal roofing system galvanized galvalume aluminum zinc stainless and copper kynar 500 finish with up to a thirty year warranty continuous length panels optional stiffening ribs and striations recommended to minimize oil canning not. Each groove bead or line will compound the strength and can also add a design to the panel. New accurl 125t sheet metal bending machine 6mm hydraulic press brake wc67y 125t 3200 for china duration.

The stretched metal in those areas will hold tension in the panel and give it structural rigidity.