High Volume Sheet Metal Cutting

Heat can have a negative effect changing the structure and properties of metal.

High volume sheet metal cutting. High pressure water cutting is using high speed water jet mixing carborundum to cut sheet metal. Laser cutting sheet metal. These processes are done in house saving valuable lead time for our customers. Xometry offers punching laser cutting waterjet cutting stamping and bending sheet metal services.

Sheet and plate generally refers to rolled metal with a high surface area to volume ratio. Laser cutting precision profiling and cutting of stainless steel mild steel and aluminium can be undertaken for sheet and plate up to thicknesses of 20mm 25mm and 12mm respectively. It can not only cut easy burst material when adopting thermal cutting such as ceramic and glass but also high reflective material for lasers such as copper and aluminum. We produce highly repeatable lengths without end deformation distortion or delamination and do it far more economically than competing methods.

On all but the thickest materials we can achieve geometric accuracy of 0 1mm. Technimetals is a single source supplier for the manufacturing of precision cnc machine components sheet metal fabrication painting and assembly. Bends in sheet metal are manufactured using sheet metal brakes. Our edm cut off is highly specialized for pins probes and other high volume small diameter solid metal parts.

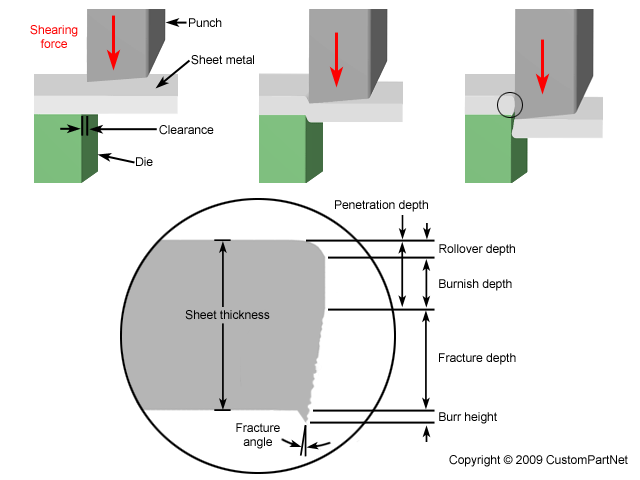

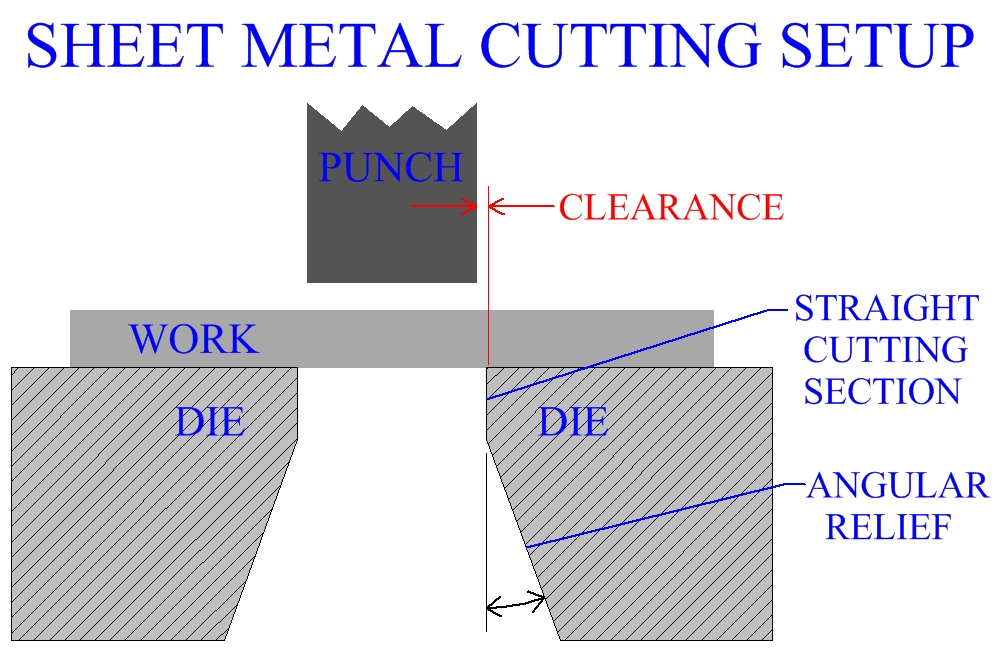

Specializing in high mix low volume 100 pieces. Most of the sheet metal cutting processes discussed can be performed on both sheet and plate metal although for many sheet metal operations difficulties will arise with increasing plate thickness. It has almost no restriction on the material and the thickness of cutting almost can reach 100mm. Typically less than 1 degree of taper.

Laystrom is a full service provider of precision sheet metal fabrications and component parts value added assemblies and low and high volume metal stampings. Dalsin industries offers high volume sheet metal fabrication welding and metal product focused contract manufacturing services to oems around the world. The difference is that sheet metal is under 1 4 inch 6mm in thickness while plate metal is thicker. Our comprehensive sheet metal fabrication capabilities include laser cutting with fiber technology automated full sheet punching automated panel bending and cnc forming robotic and manual welding aws certified structural welding spot welding assembly powder coating and finishing.

Our full complement of capabilities include. Plastic 3d printing plastic 3d printing is one of the fastest and most cost efficient methods available for the iterative design prototyping and production. A 1 degree tolerance on all bend angles. Our methods result in parts with the highest cpk and ppk process results.

Fabrication services range from low volume prototyping to high volume production runs. Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured. High volume precision sheet metal fabrication.