Henry Roof Coating Drying Time

Henry 107 asphalt mulsion sealer dampproofere at a rate of 3 4 gallons per 100 square feet.

Henry roof coating drying time. The time span difference really depends on weather conditions. Emulsion base coat must be fully cured before applying reflective coating. Help reduce the amount of air conditioning required. Seal leaks before he201 fibered black roof coating is applied.

Dew and high humidity will cause the coating to take longer to dry. Generally speaking roof coatings take 8 24 hours to thoroughly dry. Henry cool roof products can. Between 2 heavy coats of henry 204 plastic roof cement 505 flashmaster or 906 flashmaster plus wet or dry flashing cement applied over and at least 2 inches beyond repair.

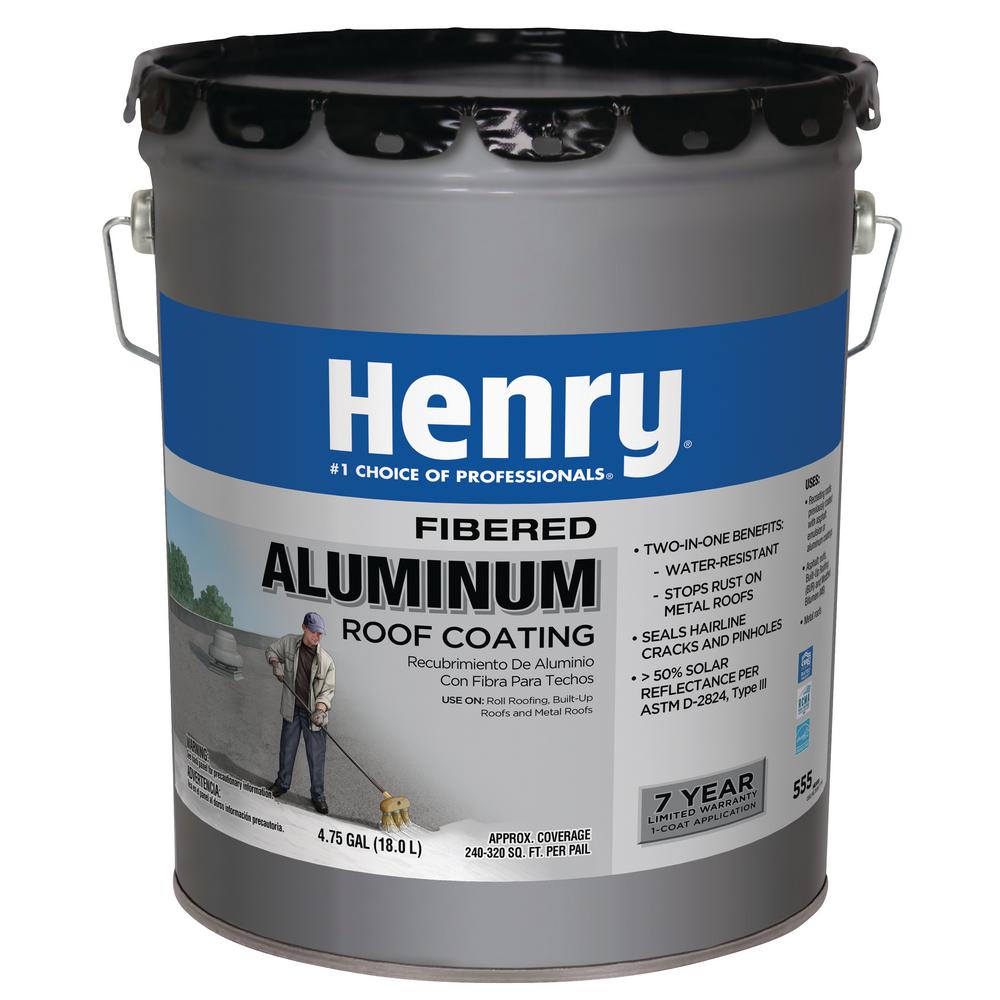

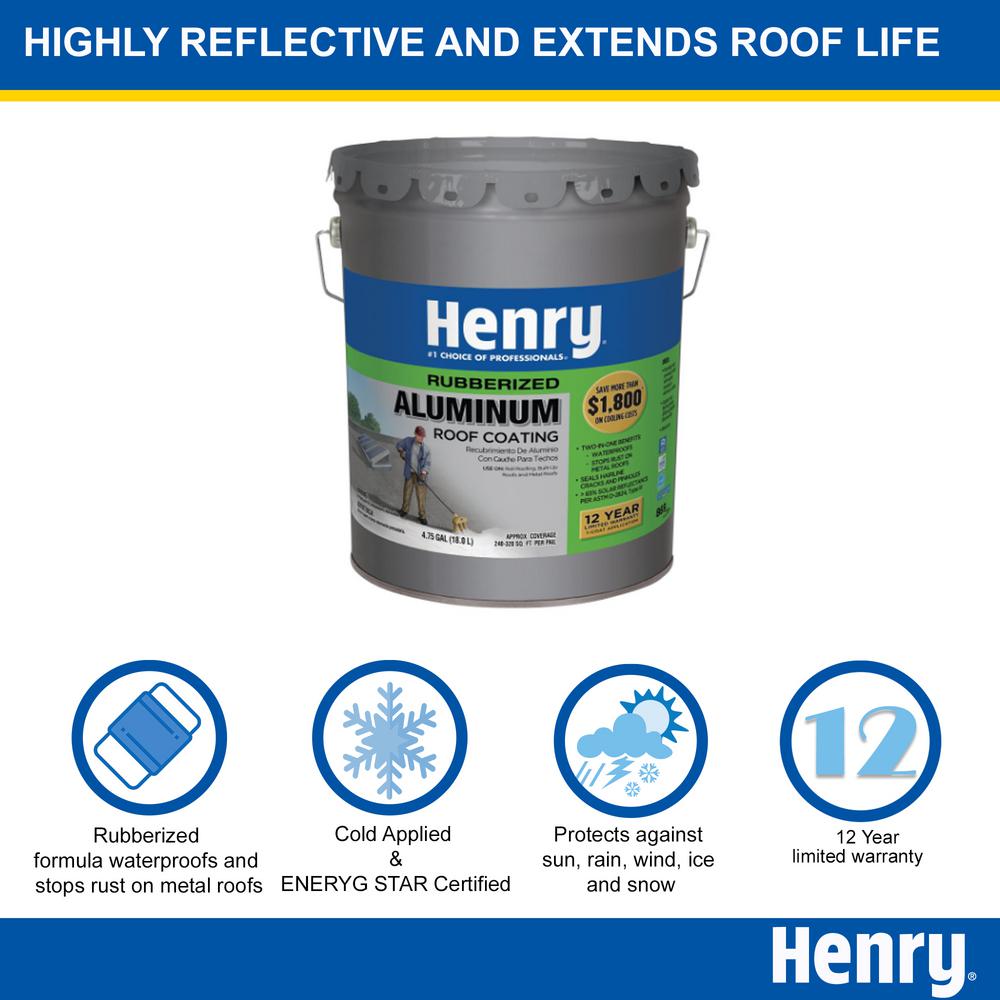

With a henry cool roof coating a roof will reflect most of the sun s heat and uv rays help reduce energy bills extend roof service life and improve occupant comfort. Fibered aluminum roof coatings provide the best coverage and dry fastest when outdoor temperatures are between 60 100 f 16 38 c with low humidity. Usually in 3 7 good drying days. X research source exposing the coating to excess moisture can result in a splotchy inconsistent finish.

Application stir coating thoroughly. Usually in 3 7 good drying days. Hot temperatures with dry weather will allow the coating to dry at a much faster rate. Emulsion base coat must be fully cured before applying reflective coating.

Henry 107 asphalt mulsion sealer dampproofere at a rate of 3 4 gallons per 100 square feet. Reflect up to 88 of the sun s heat and uv rays.