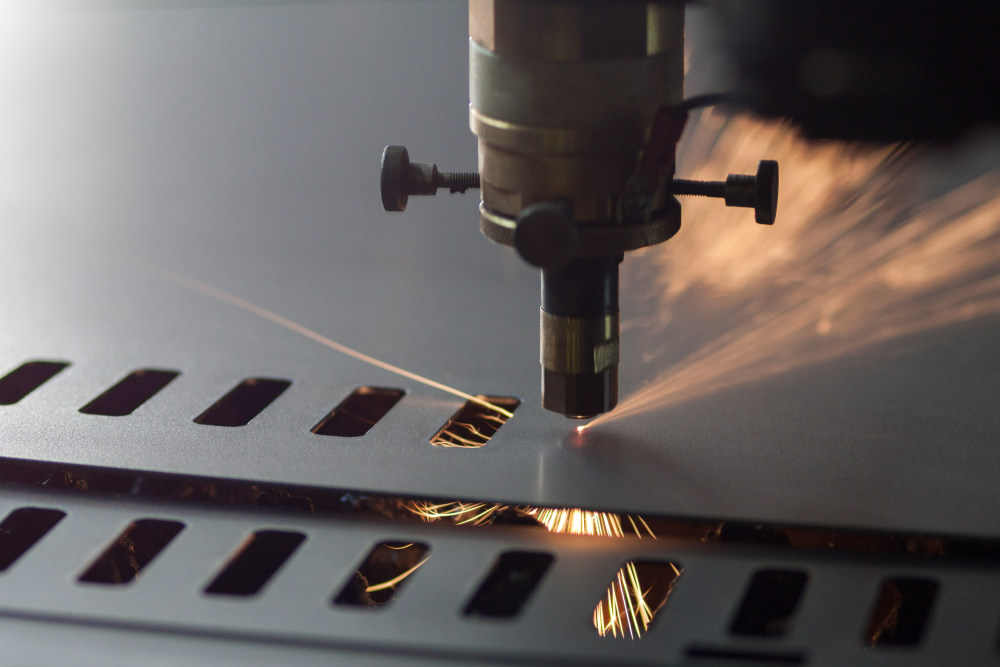

Haz Zone Sheet Metal Cutting

It can often be recognized by a series of brightly colored bands also visible near welds.

Haz zone sheet metal cutting. When this surface is put under high temperatures it s prone to changing its chemical structure. The area between the melt part and the unaffected base metal undergoes chemical and structural modifications and is called heat affected zone haz. For example laser processing produces a haz of about 18 millimeter on 7 millimeter thick 4140 steel. Most sheet metal cutting techniques are based on localized melting of the material.

It s called the heat affected zone haz. Laser cutting heat affected zone tvp materials 27 jan 06 15 25 there is definitely a microstructural change in the haz but the discoloration part of this can be influenced by electropolishing and or passivating. The area between the melted part and the unaffected base metal undergoes chemical and structural modifications. Some manufacturing procedures that produce the haz are mechanical cutting thermal cutting and welding.

This can be seen by warping bending or wearing away at the surface. In carbon steel the higher the hardenability the greater the haz. Most sheet metal cutting techniques are based on localized melting of the material see figure 1. The heat generated by the laser cutting process and after cooling causes this change in the region near the cut surface.

The heat affected zone haz is the zone of the base material which has not melted but whose microstructure and mechanical properties were affected by the heat generated during laser cutting. The heat affected zone haz is the part of a metal surface that is exposed to high heat levels. The heat affected zone or simply haz is something that occurs when metal is subject to high temperatures. It has a negative impact on the design and structure of the metal.

In laser cutting this is localized near the cutting zone. A haz forms in metals when the temperature rises above the critical transformation point. These devices have a considerable share in the market on one hand they re all well known on the other hand they re cheap. It can often be recognized by a series of brightly colored bands also visible near welds.

The area between the melt part and the unaffected base metal undergoes chemical and structural modifications and is called heat affected zone haz. As a traditional sheet metal cutting equipment there are mainly numerical control and non numerical control shears presses flame cutting plasma cutting high pressure water cutting etc. This article discusses those effects and how to reduce them. A heat affected zone haz is the portion of the base metal that was not melted during brazing and cutting welding but whose microstructure and mechanical properties were altered by the heat.