Hard Tooling Sheet Metal

Difference between soft tool and hard tool soft tool.

Hard tooling sheet metal. Hard tool is a high quality tooling for mass production it s made of the best quality steel like h13 420 etc. Hard tooling feeds coiled sheet metal into a stamping press where a steel die forms the metal in one or more stages. There are some cuts that you can do with decent tin snips. Figure 7 shows small steel parts being cut out of thinner sheet metal.

Hard tools have to be made by third party vendors who specialize in such materials because they require precise machining and polishing. Stamping includes a variety of sheet metal forming manufacturing processes such as punching using a machine press or stamping press blanking embossing bending flanging and coining. This is also known as sheet metal bending sheet metal punching or sheet metal forming. These bags are commonly used for initially shaping sheet metal also known as roughing before it s finished on a solid surface such as a forming block dolly or anvil.

Hard tooling steel aluminum tools are used for the injection molding process for prototype or bridge but these tools are mostly used for high volume production 100 s 100 000 s steel aluminum tools typically range in price from thousands to tens of thousands of dollars. Hard tools are tools made of metals. The 900 per hour the hard tool produces. Anvils hammer and shape metal on these anvils.

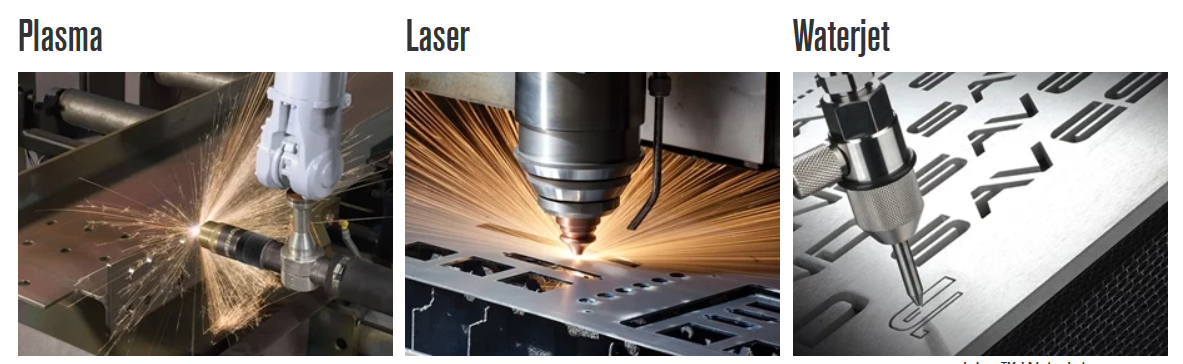

The key to a good hard tool is the surface finish. Contact us about our standard and custom tooling. Soft tooling uses lasers turrets and brake presses to form parts and components through cutting punching and bending. Further adding to the cost difference are the expenses for consumable such as gases required for the plasma table s production.

Per minute or 240 per hour vs. They look like scissors and work fine with sheet metals like brass aluminum tin steel etc. Tooling solutions for sheet metal fabrication hard tooling compression tooling additive manufacturing. Sheet metal forming bags hold any shape workpiece steady while you pound on it with a hammer.

Stamping also known as pressing is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Such as straight cut snips left cut the right cut etc. This typically means steel and nickel alloys capable of withstanding thousands of production cycles. Hard tool requires more procedure and longer time to manufacture.

That is a production rate of 4 pc.

.png)